Company History

Introduction of company

- Company name:SINO-JAPAN CHEMICAL CO., LTD.

- Established date:1970/5/13

- Capital:NTD144,732,000

- Head Office:14Fl, No.99, Sec. 2, Jen Ai Rd., Taipei 100014, Taiwan

- TEL:+886-(0)2-2396-6223

- Factory:No. 6, Shih Hwa 4th Rd. Lin-Yuan Dist., Kaohsiung City 832518, Taiwan

- TEL:+886-(0)7-642-6311

Company History

1970

.The company was established.

.The Shulin factory was set up to produce emulsifier for pesticide formulation form the beginning.

.The Shulin factory was set up to produce emulsifier for pesticide formulation form the beginning.

1978

.The R&D section was founded.

1982

.Came into operation of the EOD factory at the Linyuan Petrochemical industrial Park.

.Specialized in manufacturing of non-ionic surfactants.

.Specialized in manufacturing of non-ionic surfactants.

1988

.Completed the factory's automation control and monitoring system.

1991

.Set up the production facilities for specific high boiling point solvent at the Linyuan plant.

1993

.Relocated the company to the present address at Jen Ai Road, Taipei City (Fook Kee Building).

1997

.The Linyuan plant was certified for the ISO-9002 Quality Management System.

2000

.Commenced the distributed control system (DCS).

.Introduced the WINDOWS client-server model computer system.

.Set up a 20MT reactor and an 800MT storage tank.

. Acquired the certification of the ISO-9001 Quality Management System.

.Introduced the WINDOWS client-server model computer system.

.Set up a 20MT reactor and an 800MT storage tank.

. Acquired the certification of the ISO-9001 Quality Management System.

2002

.Raised the Technical & Q.C. Building and the Pilot plant.

2004

.Increased the capacity of material storage tank to total 700MT.

.Set up the online electronic scales system.

.Set up the online electronic scales system.

2005

.Built up the EHG distillation tower.

.Broadened the product lines from industrial-grade to electronic-grade.

.Broadened the product lines from industrial-grade to electronic-grade.

2006

.Obtained the certification of the ISO-14001 Environmental Management System.

2007

.Added a 30MT reactor.

.Obtained the certification of the OHSAS-18001 Occupational Health and Safety Management System.

.Obtained the certification of the OHSAS-18001 Occupational Health and Safety Management System.

2008

.Nippon Shokubai Co., Ltd. Became the largest shareholder of the company.

.Set up the flake-form making plant and warehouse.

.Set up the flake-form making plant and warehouse.

2010

.Installed a 15MT high temperature reactor to increase the production capacity of the ester products.

2011

.Constructed the automatic storage and retrieval system with a capacity of 2200MT.

2012

.Invested a 50MT high temperature reactor.

2013

.The addition of "wet and dry particle size analysis" equipment.

.Formally introduced "Total Production Management" (TPM).

.Formally introduced "Total Production Management" (TPM).

2014

.Initiation of the high molecular weight polyethylene glycol powder grinding equipment.

2015

.Acquired Taiwan Occupational Safety and Health Management System (CNS15506).

2017

.Established an automated storage & retrieval warehouse with storage capacity of 2,200 MT in 2016

.In 2017, another 1210 MT of storage capacity is expanded.

. Set up a new automated packaging systems

.In 2017, another 1210 MT of storage capacity is expanded.

. Set up a new automated packaging systems

2018

.Setup of C-3501 refining reactor.

.Initiation of SAP ERP system.

.Initiation of SAP ERP system.

2019

.Attained ISO-45001:2018 Occupational Safety and Health Management System

2020

.Office space in Taipei headquarters is expanded. (13F & 14F)

.Offsite backup systems of data server are set up in Taipei headquarters and Linyuan plant.

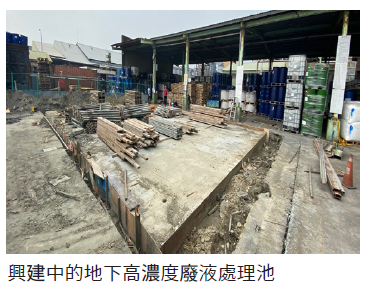

.A 300M³ underground high concentration wastewater treatment pond isadded.

.Offsite backup systems of data server are set up in Taipei headquarters and Linyuan plant.

.A 300M³ underground high concentration wastewater treatment pond isadded.

2022

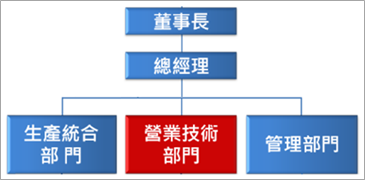

.To strengthen SJC’s product development and customer response ability, the Sales & Marketing Division and Research & Technology Department have been merged into a new division named "Customer Solutions Division".